Description

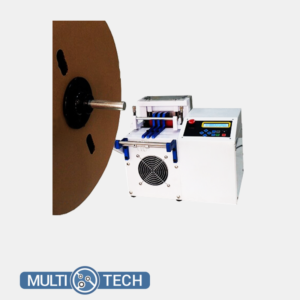

Insulated Ferrule Fastening Machine | MT-206

- It uses the cassette die method, which can be changed easily compared to the 2.0T end ferrule machine.

- It is controlled by microcomputer CMOS chip with human program design, which is safer and more reliable.

- The use of loose ends instead of expensive roller ends provides economy.

- The centrifuge has features such as free feeding, frequency conversion speed regulation, precise cylinder position and unit connection standard.

- The working speed of loose ends is the same as compared to roller ends, but it saves labor and economy; It also improves cost performance.

- It has special movable wheels that make the movement more consistent.

- It can be used as a 2.0T crimping machine when needed; 800#,2000# values can be provided and side feed or back feed die can be used.

TECHNICAL PARAMETERS

| Engine | 250 W |

| Work Lamp | 60 W |

| Vibration Plate | 120 W |

| Crimping Capacity | 2.0 T |

| Slip Block Stroke | 30 mm |

| Number of Bending | 120 pcs/min |

| Closure Height | 126 mm |

| Closing Height Adjustment | 10 mm |

| Voltage | AC 220 V/50 HZ |

| Weight | 160 kg |

| Dimensions | 450 * 800 * 1200 mm |