Description

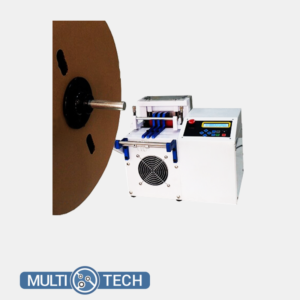

Dual Axis Laser Diameter | MTLT-25XY; is used to measure cables, wires, hoses, pipes, strips, glass, etc. coming out of the extruder in the production line. It is designed for diameter measurement of transparent or non-transparent materials. It can control the working speed of the extrusion machines so that the products coming out of the production line are in the desired diameter.

- It adopts laser scanning technique, and the measuring range is very wide.

- Small volume, light weight, strong anti-jamming.

- High measuring accuracy and good repeatability.

- RS485 communication interface enables it to communicate online with PLC, PC.

- High precision F (θ) mirror. Analytical shake can affect normal measurements.

- No outside noise and fog affect the measurement stability.

- Scanning speed: more than 800 per second

TECHNICAL PARAMETERS

| Accuracy | 2µm±0.02%ty at 25℃ when the product is centered |

| Design | Double shaft |

| Measuring Range | 0.1~20mm |

| Door Size | 25mm |

| Resolution | 2µm |

| Laser | Solid state laser diode. Class 2 laser, 1mW, max. λ = 675 nm |

| Scan speed | 600 Scans (per axis per second) |

| Average / Scan | Average of 64/128/256/512 Scans/second |

| Supply | AC220V±10%, 50-60Hz ≤15W |

| Operating Temperature | 5~45℃ |

| Relative Humidity | ≤80% |