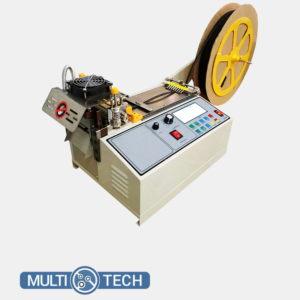

Description

MT-P20D Asian type vertical feed die suitable for terminal and thimble fastening machine. Suitable for all kinds of vertical feed terminals. 2.00mm, 2.50mm, 2.54mm, 3.00mm, 3.96mm, 4.8mm, 6.3mm etc. terminal blades can be installed. Die stroke amount is 30 mm.